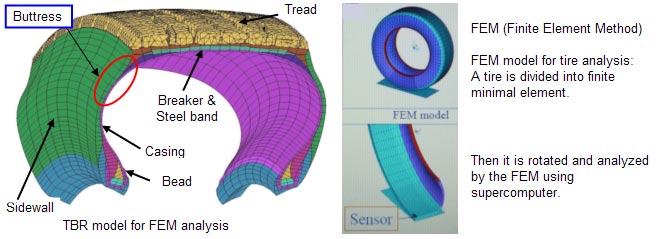

Casing profile plays a very important role in combination with the breaker package of tread in order to deliver various performance of a tire . When a tire is rotated in the computer, the stress and strain applied to each finite element is calculated and it is integrated through the whole casing from bead to bead. Generally the stress can be observed concentrated in the buttress area of the casing. Stress concentration causes energy loss, which causes heat generation. And as a result heat build-up occurs. The heat build-up is the culprit of almost all the troubles for TBR. Thus the computer simulates with FEM analysis heat distribution in a rolling tire and calculates the optimum casing profile for minimum heat build-up.